Publications

- Home

- Publications

Search by key words :

Feedback on long-term integrity of Multi-linear drainage geocomposites

The use of drainage geocomposites in landfill final covers facilitates surface water drainage, contributing to long-term stability. However, validating their durability beyond accelerated laboratory aging tests remains a challenge. The most direct method involves exhuming geocomposites after prolonged field exposure and analyzing their mechanical and hydraulic properties. This study presents two case studies involving multi-linear drainage geocomposites installed in landfill final covers, one exhumed after 10 years in France and the other after 12 years in Canada.

Gas capture and extraction using multi-linear drainage géocomposite

The design of gas drainage systems is essential for mitigating environmental impacts, especially in contaminated soils (e.g., hydrocarbons, radon) and landfill covers (e.g., methane and carbon dioxide management). This study experimentally investigates the gas drainage capacity and transport through mini pipes within multi-linear drainage geocomposites. This paper presents the methodology and results of the proposed study, along with various analyses of equivalency considerations to enhance gas drainage system design.

Environmental Design Considerations Using an Equivalency Index between Granular Drainage and Geosynthetic Alternatives

Effective drainage is essential in civil engineering projects, and the design is influenced by the required capacity, inflow rates, and the geometric configuration of the structure. Reduction factors are applied based on material and application. Drainage layers can be granular or geosynthetic, with granular layers using free-draining aggregates and geocomposites comprising non-woven geotextiles and drainage cores or pipes. This study aims to establish equivalency between granular layers and geocomposites in water drainage and gas transport, assuming equal long-term capacity under identical conditions. Despite reduction factors and safety margins, geocomposites significantly reduce drainage layer thickness compared to granular layers. The methodology adopted in this project is to present an equivalency design between granular drainage aggregates and drainage geocomposite and environmental benefit of using geosynthetics as a drainage design solution. This is supported by practical examples and environmental benefits such as reduced aggregate extraction, transportation, greenhouse gas emissions, and construction time for similar or better drainage capacity.

Design and use of multi-linear drainage geocomposites for gas collection layers

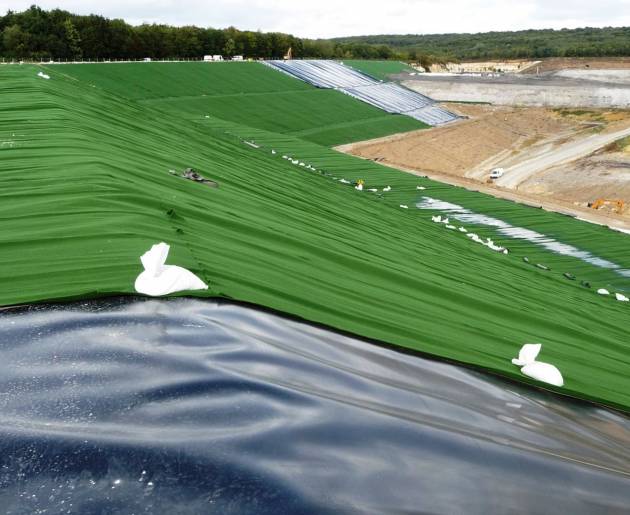

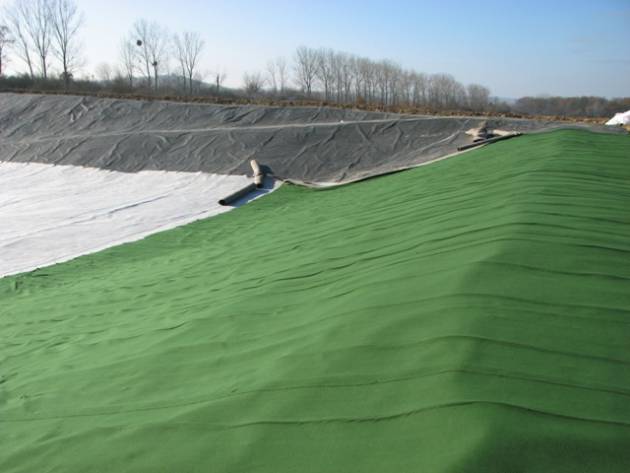

Pore pressures generated by gas underneath a geomembrane can affect its integrity and the entire lining system. It can create whales/hippos in a surface impoundment, significantly reduce normal stress on the lower interface and create a veneer instability on final landfill cover. The membrane is lifted by the pressure of the gas trapped beneath it. The solution to avoid such occurrences is to install a permeable material that collects and transmits the gas outside the lining system. It can be vented to the atmosphere in the case of impoundments or collected in a gas collection network for valorization in case of landfills, for example. A sand layer is certainly possible, but drainage geocomposites offer an efficient and economical alternative. Depending on the application, the drainage geocomposite is designed to act as a passive system (no mechanical vacuum applied) or active. This paper presents the use of multi-linear drainage geocomposite for gas collection and its hydraulic behavior to collect and evacuate the gas. A case study is also given with the use of geocomposite as venting layer under a lined pond.

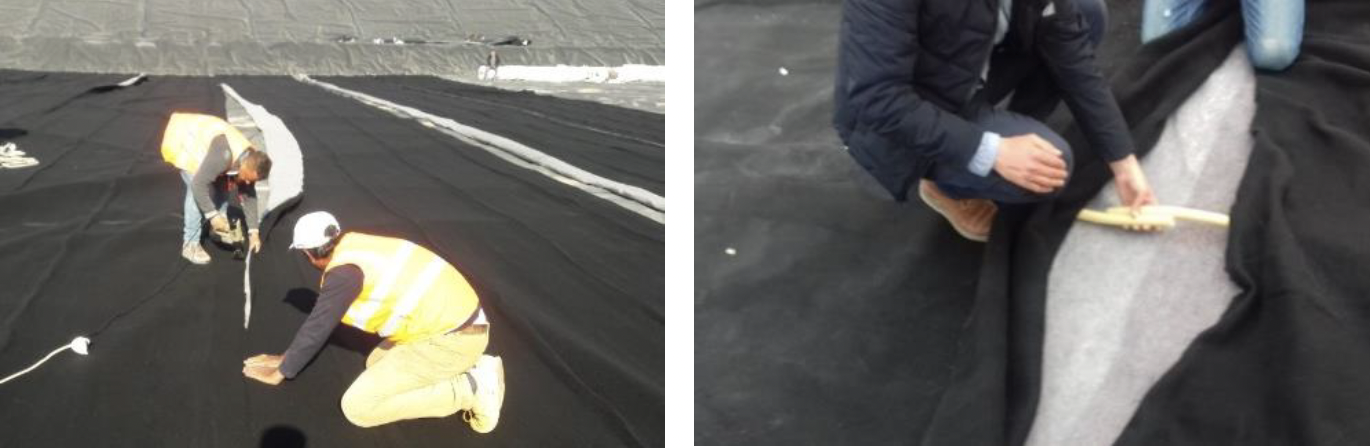

Case study on a contaminated soil landfill in Canada with a focus on geosynthetic materials and electrical leak location

Designing a double-lined landfill for contaminated soils certainly presents several challenges. Many design aspects are taken into consideration to comply with local regulations, including thickness of the natural clay layer, minimal slopes for leachate drainage, side slopes for soil stability, global design to lower stress on the geosynthetics, and much more.

We will focus on the choice of geosynthetics used for the construction of a cell on a contaminated soil landfill during the summer of 2023, as well as quality control and quality assurance, including electrical leak location. A multi-linear drainage geocomposite was selected to cover each layer of an HDPE geomembrane and a layer of natural sand was also installed. It was not practical to use sand on the secondary geomembrane in the slopes due to stability and damaging risks, therefore the drainage system solely relied on

the drainage geocomposite. To carry on with the electrical leak location, a conductive mesh was added to the geocomposite installed in the slopes, allowing 100% of the installed geomembrane to be tested.

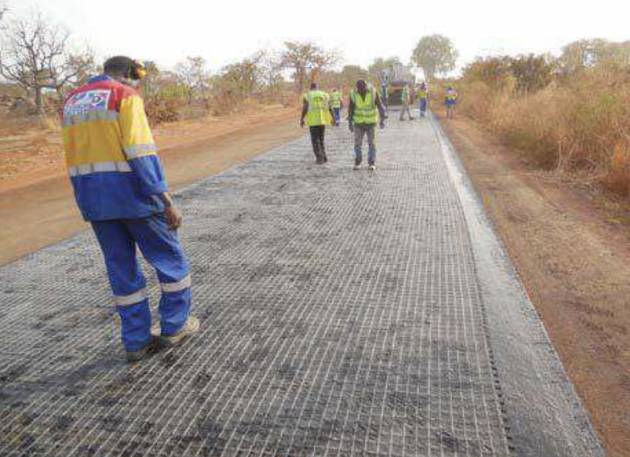

Use of high-performance reinforcement geosynthetics to stabilize access roads

With the rapid infrastructure development, the availability of competent soils is decreasing. The access roads and tracks practicability should be ensured when crossing these weak soils. The practicability of access roads and tracks is therefore important. Depending on the mechanical properties of the subgrade, the construction of access roads requires the use of granular foundation materials of significant thickness, which can result in substantial costs and construction delays. This is especially true when the runway is to be constructed on soft subgrade and possibly in the presence of water. This article presents the use of a high-performance reinforcement geosynthetic to stabilize unpaved access roads, control settlement and prevent contamination between the subgrade and the foundation. A laboratory case well documented is used. Two calculation methodologies based on the subgrade soil characteristics are provided and compared.

Lifetime considerations of geotextile UV exposure before installation

Geotextile are in most case intended for buried application, without exposure to sunlight. However, a short exposure to sunlight may occur before installation. Because of potential delay of installation and soil burying, the material is required to meet UV resistance. Artificial UV weathering will assess the potential risk of unintended exposure to sunlight. Photodegradation reactions consider the interactions with exposure conditions as well as polymer sensitivity to sunlight. Based on both laboratory measurements and field data, this paper evaluates the effect of light intensity, temperature and humidity with climates. Using polymer relation of its UV light sensitivity with the effective irradiance, a cumulative index is calculated for the reduction of geotextile service life from exposure to sunlight. Artificial weathering cycles for geotextiles are compared and related to the specific degradation mechanisms of polypropylene and polyethylene terephthalate. The reaction rate is correlated with temperature, respectively for each polymer. A model using radiant energy and temperature is proposed for guidance to service life prediction of partly UV exposed geotextiles.

DEVELOPMENT OF DRAINAGE GEOCOMPOSITES FOR GAS CAPTURE AND EXTRACTION

A gas drainage system's design is essential for controlling gas emissions into the atmosphere and consequently their environmental impact, particularly for these two types of applications: buildings built on polluted soils (hydrocarbons, radon, etc.) and landfill covers (methane, carbon dioxide). As part of a sustainable development strategy, the use of drainage geocomposites with incorporated mini-pipes presents a technical and environmental benefit specifically for these two applications. This paper describes a preliminary study for an experimental evaluation of air and water discharge capacities through mini-pipes in order to ultimately extend results for further kinds of gas (methane, radon, etc.) for geoenvironmental applications. Several configurations and length of mini-pipes were tested in order to model pressure losses. the verification of the equivalence of measurement of drainage capacity through mini-pipes between air and water is evaluated in this project.

Water drainage and gas collection with geocomposites - Hydraulic software

Geosynthetic materials and, more specifically, drainage geocomposites are now widely used for water drainage and gas collection in applications as varied as final landfill covers, leachate collection in landfill cells, sub-slab depressurization systems under buildings, groundwater drainage under embankments, etc. The design methods used are based on the in-plane flow capacity of the geocomposites, which is determined by laboratory tests performed on 250-300 mm long product specimens. Fluid is injected into the thickness of the product and the drainage capacity is interpolated for an actual length of several meters. This paper presents the development of a hydraulic design software for geocomposites and granular drainage layers, based on soil hydraulic and flow capacity characterization of geocomposites through laboratory tests. The software provides a model of the hydraulic curves in the geocomposites depending on the application for which the geocomposites are used, and the fluid to be drained (water, landfill gas, methane, air, etc.).

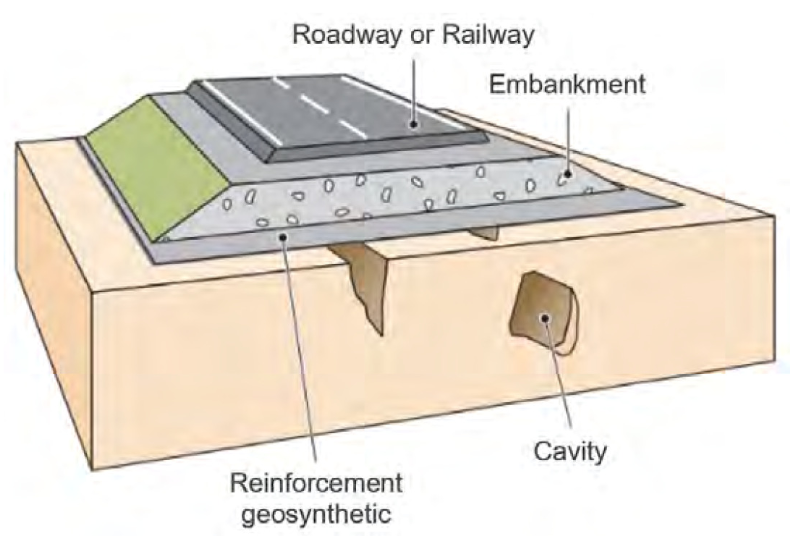

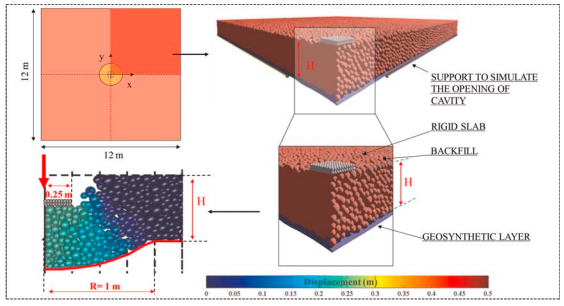

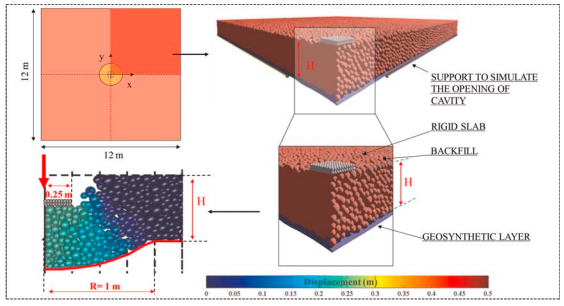

Monitoring and warning system including a bi-modulus geosynthetic for the reinforcement of cohesive soil on cavities

The use of reinforcement geosynthetics to prevent localized collapses such as cavities is common today. Numerous experimental and numerical studies allow a precise understanding of the geosynthetics behavior related to these application. Within the REGIC (reinforcement by intelligent geosynthetics on natural or anthropic cavities) research project, an innovative solution has been developed and patented by the Afitexinov company. This solution includes a specific reinforcement geosynthetic coupled with an autonomous and remote warning device to detect a localized collapse or sinkhole. This innovative geosynthetic is an inverted bi-modulus reinforcement geosynthetic equipped with optical fibers. The first modulus at lower strength allows detecting possible deformations before transmitting the load to the second modulus with higher strength. This two-stages reinforcement system guarantees a high degree of safety from the start of the failure.

The new geosynthetic solution presented in this article aims to reduce the costs and time related to the installation of a monitoring system on a construction site. This solution’s installation and set-up do not require an expert on-site, thanks to a standalone monitoring box. This Preditect system is able to monitor large critical areas for ground deformations and detect potential underground failures. In case of any unexpected event, it will launch an automatic alert.

Innovative mechanically stabilized earth walls with geotextile geocells

Structures reinforced with geosynthetics consist in increasing the mechanical performance of a soil (mainly shear resistance) by associating it with flexible geosynthetics inclusions. One of the important issues in the construction of geosynthetic reinforced walls is the supply of natural backfill materials with the required properties needed for the stability of the wall. Indeed, unlike geosynthetics that exhibit stable properties due to extensive quality controls during the manufacturing process, soil matrix will vary from a site to another and even from the beginning to the end of the excavation work. It influences the soil stability itself and also the soil-geosynthetic interface.

As it minimizes the influence of soil characteristics on the stability of the reinforced structure, M3S geotextile geocells make possible, in addition to the construction of reinforced structures with complex shapes, to reuse the soil material excavated on-site to build the wall, including those with very poor geotechnical characteristics.

This publication presents the M3S cellular system and its mechanical and functional characteristics. It also gives a case study on the construction in 2019 of two MSE walls as part of the A71 motorway bypass on the APRR network, France.

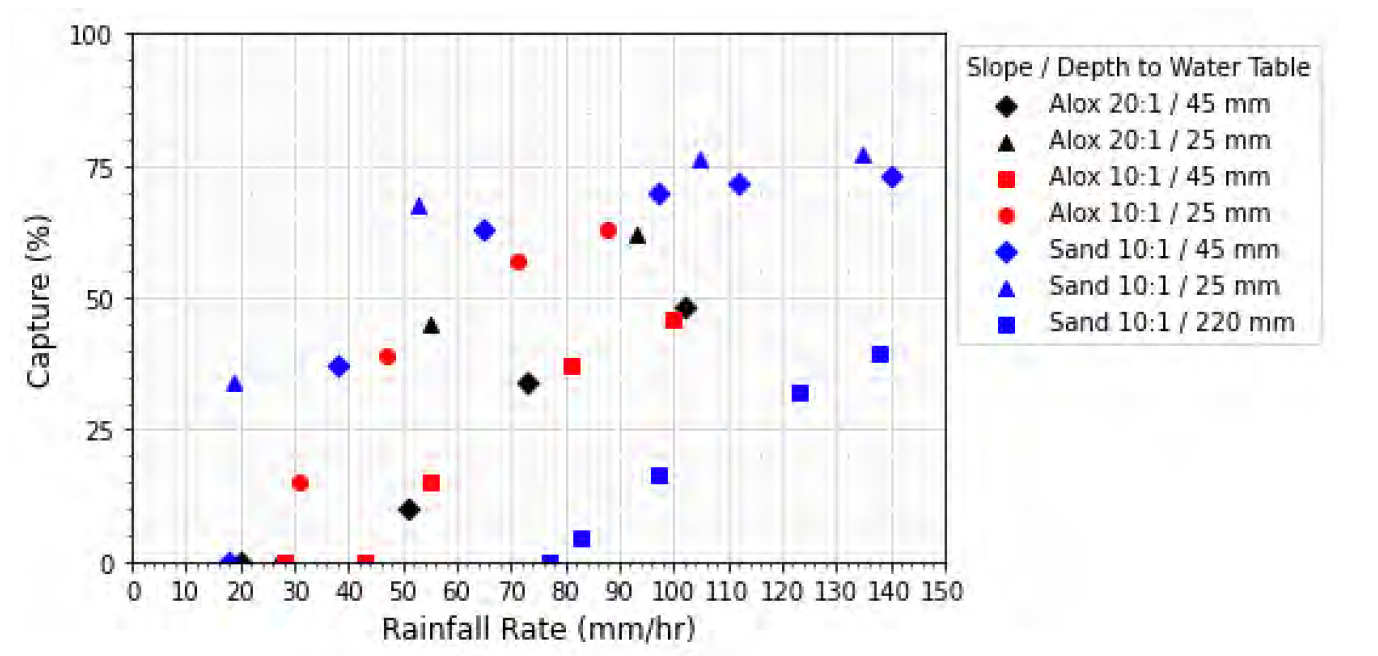

Large-scale laboratory testing of the performance of geosynthetic mine waste covers

The low permeability of geomembranes has made them a useful material for preventing contaminant leakage from many containment facilities, such as landfills and lagoons. This same characteristic also makes them an attractive choice for cover applications, particularly in the mining industry. However, geomembrane covers have not been widely adopted due to a lack of published research on their effectiveness. To address this lack of research, a large-scale laboratory study was done to quantify the amount of leakage obtained through a defect in a geomembrane cover. The leakage rate was assessed for a variety of slope angles, rainfall rates, surface microtopography, and defect sizes, shapes, and locations. The leakage rate was found to depend on all of these factors to varying degrees.

Leachate drainage by technical geocomposite at Sofa sanitary landfill

In 2018, the Municipal Development and Lending Fund of Palestine started the construction of Sofa sanitary landfill at Al Fukhkhary. The lining system of the bottom was initially constituted of a 2mm-thick HDPE geomembrane, a protective geotextile and a 0.45m-thick gravel draining layer, on a surface of around 60000m2. A design has been made to propose a drainage geocomposite with mini-pipes Draintube, able to have the same hydraulic properties as the draining layer. The choice of the product considered the whole geometry of the project (waste thickness, geometry of the bottom…) as well as the project requirements (mechanical specifications, etc.), as it also provides a mechanical protection of the lining system. Using geocomposite with mini-pipes allowed to save 27000m3 of draining gravel. In addition, the technology of this geocomposite with mini-pipes avoids biological clogging and thus guarantees its efficiency through time. In order to create a prefilter between the geocomposite with mini-pipes and the waste, a 0.15m-thick protective layer has been installed. By calculating the retention criteria, it has been shown the adequation between the opening size of the filter of the geocomposite and the sieve analysis of the protective layer.

Lessons Learned on the Performance of Multi-Linear Drainage Geocomposites for Mining Applications

Tailings dewatering is a permanent concern for responsible mining companies. Soft and wet tailings can generally lead to stability issues in retaining ponds or dams, excessive environmental footprint because of their high water content and therefore a high volume to storage, and finally can increase the total process costs to a level that can eventually break the fragile equilibrium of the operation. This situation has become among the key issues to be solved, with higher environmental pressures and regulation authorities, as well as a market struggling since almost a decade. Traditional drainage geocomposites are commonly used in applications where the flow to be drained is average, the loads on the product are in the order of 500 kPa and the fines content of the soil to be drained is low. This paper presents a review of laboratory evaluations conducted on Multi-Linear Drainage Geocomposites (MLDG) to assess their applicability in tailings dewatering. Three studies were conducted. First, transmissivity tests were performed under very high normal loads, up to 2MPa, to reflect normal loads actually experienced in tailings and dams. Long‐term flow tests were then conducted during 90 days. In addition, filtration tests modeling the mechanisms involved in the deposition of tailings in a slurry form were performed, using a modified version of ASTM D5101. A scale test has been conducted in Morocco accordingly. All these tests were found to be conclusive and confirmed the applicability of MLDG for tailings dewatering applications. A case study of a recent project in Canada will be presented as well.

Multi-linear drainage geocomposite for sub-slab depressurization and radon mitigation

Sub-slab Depressurization (SSD) aims to reduce building occupants’ exposure to toxic gases from the soil. These gases can either be generated from contaminated soils (like Volatile Organic Compounds or Landfill Gas) or naturally present in the soil (like Radon). The SSD system is composed from the bottom to the top of a separator geotextile, a drainage layer, and a vapor barrier. One or more gas pits are located according to the gas concentration in the area and to the geometry of the building. Because most of the SSD systems are constructed in high-density population areas (e.g., new construction in old industrial zones), the truck traffic and the noise resulting from the excavation works, and the transportation of granular material is a nuisance for residents. It also damages the local road network that is not designed to handle heavy vehicles traffic. This paper presents the sizing and the use of multi-linear drainage geocomposite as part of the SSD system providing separation and gas collection functions. The geocomposite is composed of non-woven geotextile layers incorporating perforated mini-pipes regularly spaced and running the roll length. It is connected to a collector pipe and to the gas pit. It collects the soil gas and reduces the head losses thanks to the high-density network of perforated mini-pipes within the product and the specific fittings used to connect the product to the main collector pipe. The sizing of the geocomposite is done using laboratory tests and software to characterize the flow capacity and the head losses of the system. Multi-linear drainage geocomposites have been found to be efficient for both passive and active SSD systems.

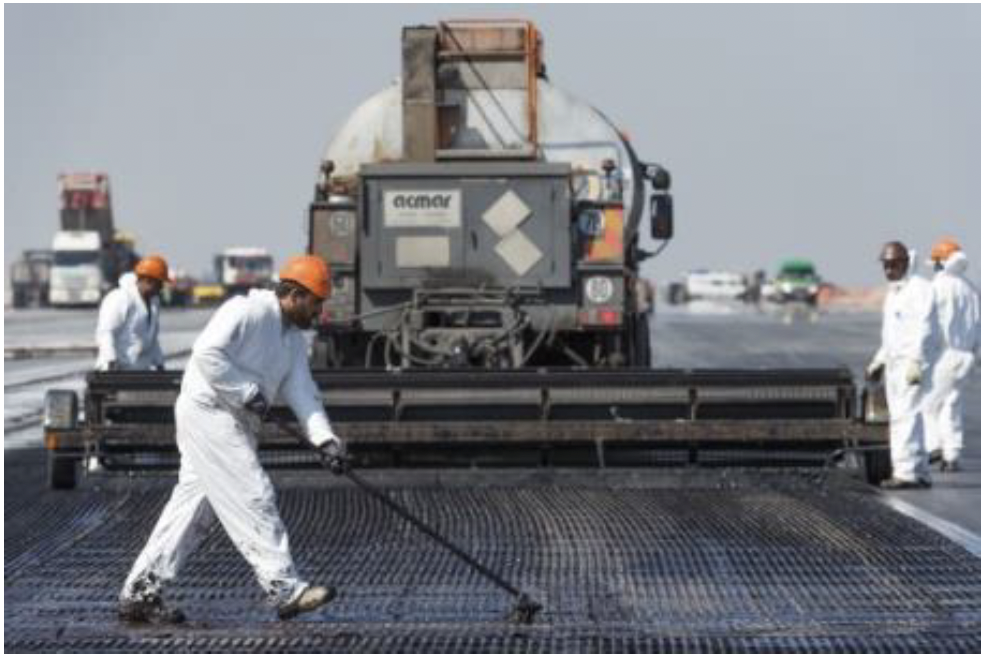

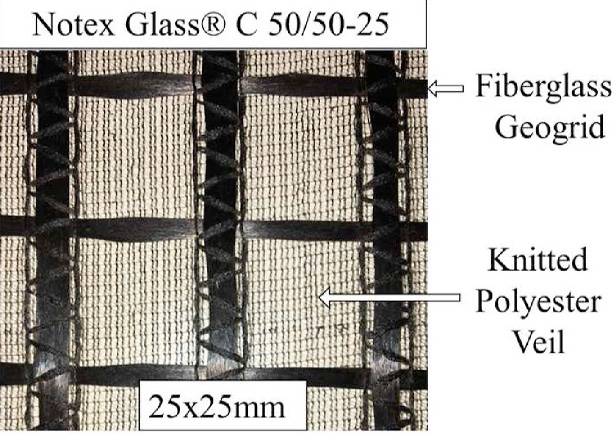

Optimization of Geosynthetic Design for Asphalt Pavement Reinforcement

The use of geogrids for pavement reinforcement has been continuously increasing over the past decades. Their main role remains to limit crack reflection and they are therefore typically used on cracked pavements before renovating the upper asphalt layers. Still, the way they work remains a debated issue and no clear guidelines currently exist for selecting this type of products in view of a specific construction project. This paper presents our current understanding of the mechanisms behind asphalt pavement reinforcement in view of the 3 functions described in the European standard for these products (EN 15381), namely stress relief, reinforcement and interlayer barrier. As a consequence, an optimal geosynthetic design can be inferred, based on the combination of a fiber-glass geogrid and a light geotextile as exemplified by the Geoter® FNG product range developed at Afitexinov. The interest of these products is discussed and illustrated in the light of recent results.

ON THE PERFORMANCE OF GEOGRIDS FOR ASPHALT PAVEMENT REINFORCEMENT: LABORATORY EVALUATION AND SELECTED CASE STUDIES

The use of geogrids for pavement reinforcement has been continuously increasing over the past decades. Their main role remains to limit crack reflection and they are therefore typically used on cracked pavements before renovating the upper asphalt layers. Still, evaluating their performance is not a simple task because most available testing methods are still at an early development stage with sometimes limited field validation. As a consequence, no clear guidelines currently exists for selecting this type of products in preparation of a construction project. This paper presents the laboratory results gathered so far on fiber-glass reinforced geocomposites in view of their use in real jobsites. Fatigue testing and the potential to delay crack reflection as measured with the Cerema Autun device, are presented and discussed in the light of recent jobsites on Paris Charles de Gaulle Airport and French highway A7. In addition, the correct positioning of the geogrids on the asphalt support was further evaluated using the Leutner test. This clarifies the conditions under which the placement of these materials will be optimized. From this work, a clearer picture tends to emerge on how to specify these very specific products in order to maximize their benefit for extending pavement life time.

Design and set up of geosynthetic reinforcement in the case of landfill piggyback expansion

The aim of this paper is to present the installation procedure and design method used in the case of a real vertical extension project on an old landfill, an operation also known as “piggyback expansion”. First, the installation steps are presented for a project in Champi-gny-sur-Yonne (France). Then, the assumptions and design method which allowed to esti-mate the tensile strength of the geosynthetic reinforcement required for the project are ex-posed. The method used in this project is the standard French method (RAFAEL) for the design of geosynthetics in the case of soil subsidence and sinkholes. Latest improvements suggested in the literature for this method are also exposed in this paper.

Keywords: geosynthetic reinforcement, old landfill extension, differential settlement.

Protection of Building Against Soil Gas Infiltrations Using Drainage Geocomposites

Construction of buildings on natural or degraded layers with the potential to generate gasses (biogas from waste, gas emission from polluted soils, radon, etc.) requires the installation of a gas collection and evacuation system to protect the health of the building’s inhabitants. Replacing crushed stone drainage layers using perforated collector pipers with a multi-linear drainage geocomposite composed of non-woven geotextile layers, needle-punched together with perforated and corrugated polypropylene pipes regularly spaced inside, typically every 1 m (40 in.), allows for the collection of gasses across the covered surface and significantly reduces excavation work and worksite traffic. As part of an active or passive subslab depressurization system, multi-linear drainage geocomposites reduce vacuum dissipations. A specific set of connectors is available to optimize the connections between the geocomposite layer and the collection pipes.

Remediation of a former quarry and permanent containment of buried toxic materials

The site of the former Landreville quarry, owned by Les Carrières Rive-Sud Inc. (CRS), was used for stone extraction, and crushing operations until 1992 and was the scene of illegal dumping of toxic waste. A remediation plan for the quarry was approved by the Ministry of the Environment of Quebec in 2015, and work began in the spring of 2018. The remediation work consists of containing the toxic materials buried in a portion of the quarry and backfilling a part of the flooded area of the CRS site to secure the wall of the former dump. This required approximately 2.5 million cubic meters (3,300,000 yd3) of clean soil and coarse materials (concrete, brick, and rock) to be imported to the site. The final cover system includes a geomembrane, a drainage geocomposite for rainwater drainage and mechanical protection, and a drainage geocomposite for gas collection. The CRS site remediation plan also includes gas treatment and groundwater quality monitoring. This paper presents the various technical requirements for the site remediation and explains how the different geosynthetics selected and implemented were able to meet the project expectations.

Retaining walls with high weight concrete blocks in association with geosynthetics

Geosynthetic reinforced retaining walls with cellular facing are well-known and mastered technics commonly used in France and around the world. This technic combines cellular blocks (such as concrete, gabion baskets…) with high modulus reinforcement geosynthetics and allows the retaining wall to resists stresses on very high heights. However, the installation procedure of these blocks knows some limits for great projects such as the duration of installation or how to deal with a draining system behind the facing. That’s why the idea of the creation of a block with new size, new weight and new composition came on the table. This concrete block with almost 1 m² of facing area per block and 700 kg empty allows the use of an hybrid solution part-weight/part-geosynthetic reinforcement while ensuring an extremely fast and easy on-site installation with classical lifting engines.

STUDY OF THE STABILITY OF A SEA DYKE IN LA COUARDE SUR MER USING GEOGRID

Following storm Xynthia in 2010, which hit several European countries and caused an exceptional rise in water levels of nearly one and a half meter on the coast, a series of diagnoses of the existing dykes as well as of the most affected coastal towns and villages was launched in the relevant departments. The La-Couarde-Sur-Mer dyke (17) having been strongly impacted, a diagnosis of the disorders was conducted in 2015 and an extension / reinforcement project launched a few years later. Since the stability of the slopes on the mainland side was initially ensured by the installation of wooden piles, the conditions of implementation required a reassessment of the solution and the installation of reinforcement geogrids.

Keywords: Dike, Geogrid, Stability, Reinforcement, Diagnostic

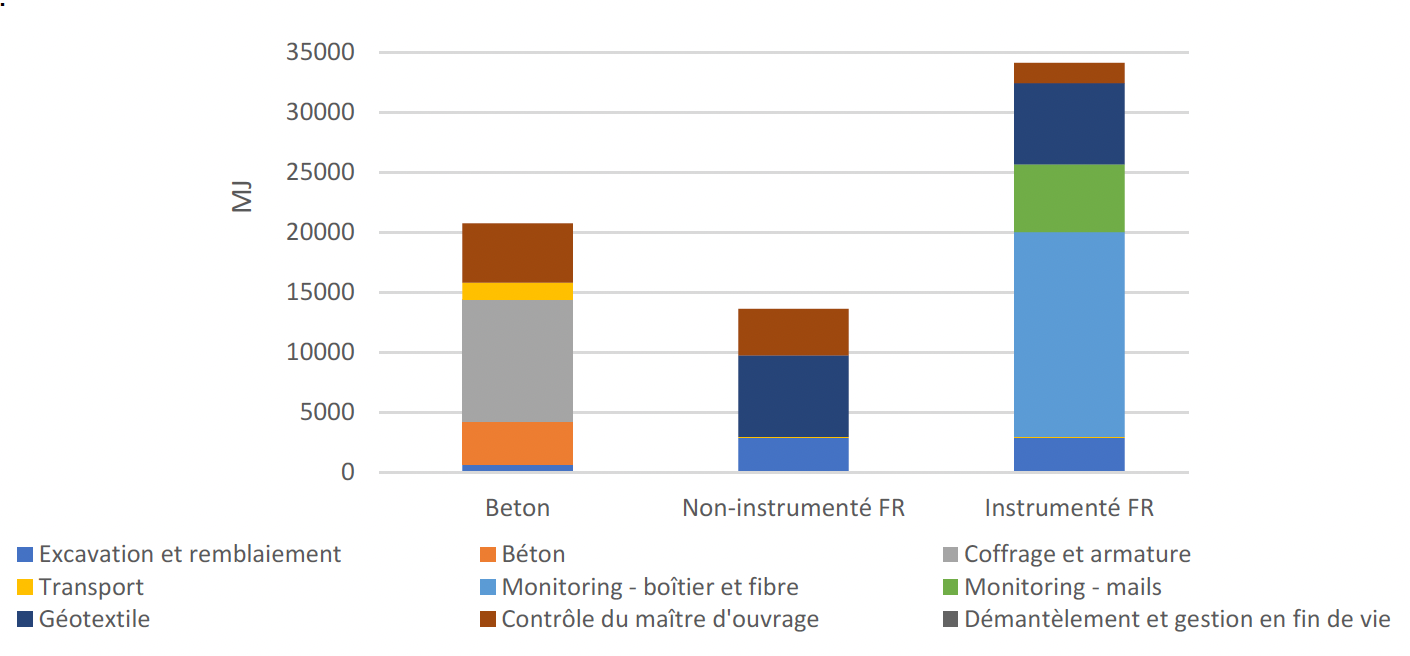

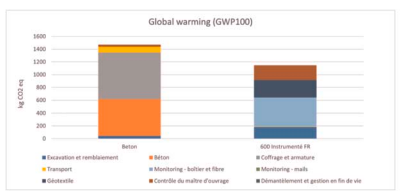

LIFE CYCLE ANALYSIS OF A GEOSYNTHETIC REINFORCEMENT COUPLED WITH A DETECTION WARNING SYSTEM

The coupling of an auscultation and warning system to a reinforcement geosynthetic is a judicious innovative solution in case of sensitive structures like areas with high risk of soil subsidence. Although there exist already some reference studies on the Life Cycle Assessment of solutions incorporating geosynthetics, it seems important to evaluate the influence of auscultation and warning system on the environmental impact and to compare it with other currently used solutions. The article presents a sensitivity analysis for identifying the most influencing parameters; it is then extended to other solutions offering the same level of performance and security to the Owner.

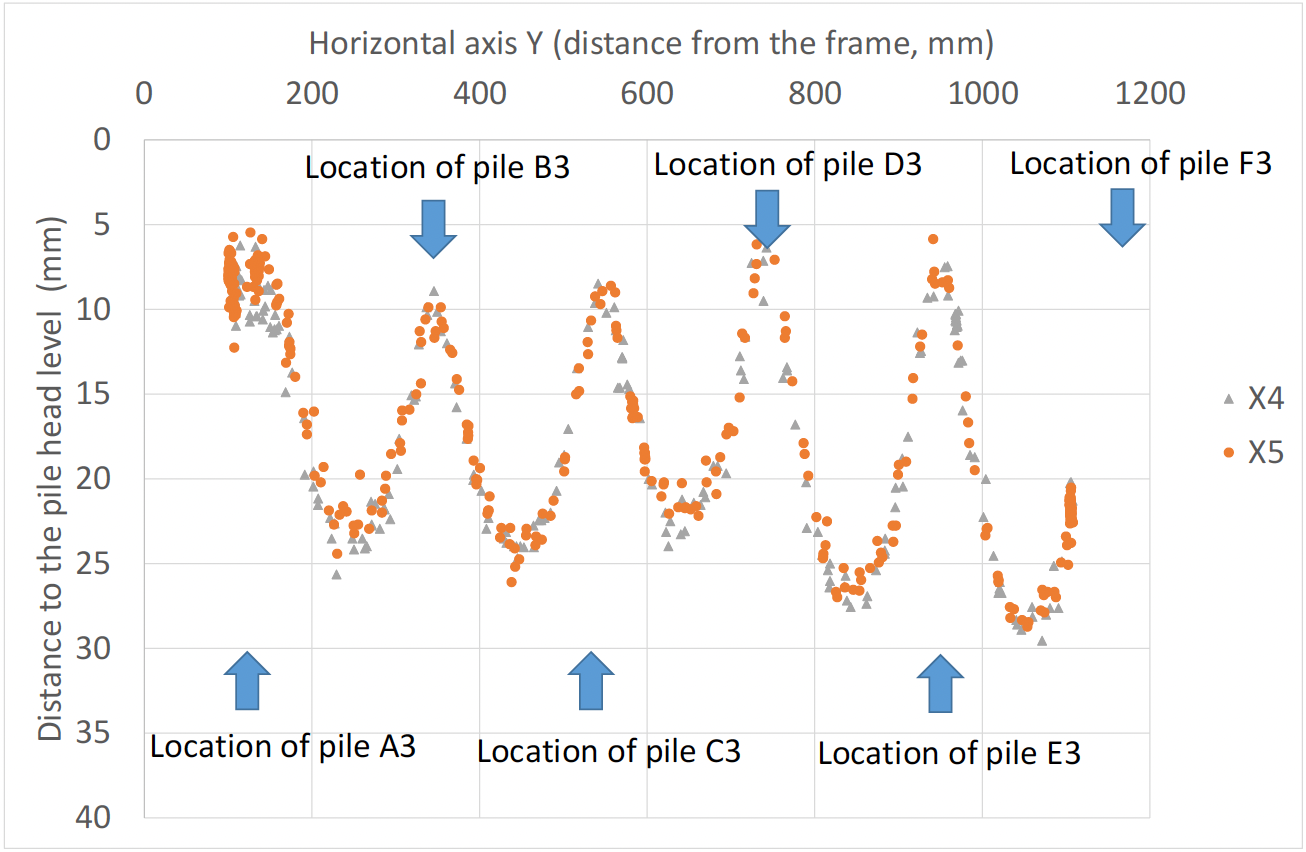

A laboratory device to analyze the behavior of pile-supported embankment reinforced by geosynthetics

Pile-supported embankment on soft soil are currently reinforced by geosynthetics. Many an-alytical methods have been developed to design the geosynthetic but they are simplistic and do not take into account all the complexity of the developed mechanisms. Despite all the difficulties met when simu-lating the behavior of pile-supported embankments in the laboratory, it is shown that 1g physical modeling tests can help one to understand the behavior. A new small-scale model, which has been developed to reproduce the behavior of pile-supported embankment at the scale 1/10. A specific study have been made to find and qualify a foam simulating the behavior of the soft soil. The first tests have validated the ability of the device to correctly simulate the behavior of pile-supported embankment.

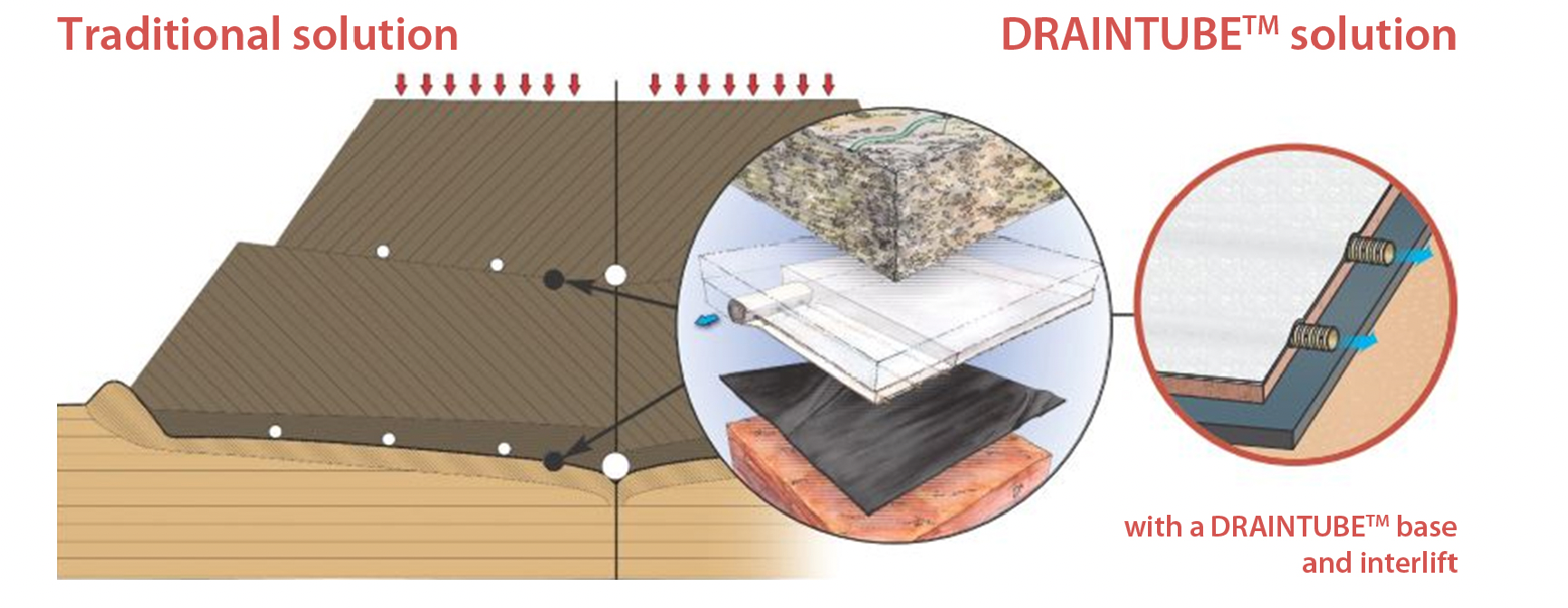

Tubular Drainage and Lining Geocomposite for Mine Tailings and Heap Leach Pads

In the last decade Afitex developed the Draintube™ geocomposite, which provides simultaneous drainage and waterproofing functions. This new type of drain tubes planar geocomposites (DTPG) differs from other geocomposites as the drainage core is composed of multiple corrugated and perforated pipes instead of biaxial or triaxial nets. It is furthermore associated with needle-punch stitched layers of non-woven geotextiles, which act either as capillary mediums or as filters.

In this paper, the structure of the Draintube™ drainage composite is presented along with its key properties and the drainage mechanism associated with its particular structure.

The relevance of this kind of structure is then reviewed based on past and current laboratory bench evaluations and field installations for mining applications such as the covering of acid rock drainage (ARD) tailings for the Central Manitoba Mine (Canada) site-rehabilitation; and as a pregnant solution collection layer in heap leach pads.

Some of the demonstrated critical advantages of Draintube™ in the mining industry are as follows:

- reduction of the thickness, hence lower volume of granular drain layers

- improvement of fluid and gas collection and reduction of the hydraulic load

- reduction of secondary collector network

- mechanical protection of the sealing membrane

- fast and economical installation of interlifts

- stability under extreme conditions (compression, temperature, pH)

- increased stability of entire covering system and reinforcement of protection of dykes

- filtration of the covered material

- customised drainage

- positive connection of the geocomposite to collector pipes

- enable leaks detection (using a conductive textile layer) with an electrical test.

Statement of the Performance of Tubular Drainage Geocomposites for Mining Applications

Tailings dewatering is a permanent concern for responsible mining companies. Soft and wet tailings can generally lead to stability issues in retaining ponds or dams, excessive environmental footprint because of their high water content and therefore a high volume to storage, and finally can increase the total process costs to a level that can eventually break the fragile equilibrium of the operation. This situation is more and more one the key issues to be solved considering higher and higher environmental pressures for the population and the regulation authorities and a market which is struggling since almost a decade. Traditional drainage geocomposites are commonly used in applications where the flow to be drained is average, the loads on the product are in the order of 478 kPa and the fines content of the soil to be drained is low. This paper presents a review of laboratory evaluations conducted on Enhanced Flow Drainage Geocomposites (EFDG) to assess their applicability in tailings dewatering using laboratory evaluations. Three studies were conducted. First, transmissivity tests were performed under very high normal loads, up to 2MPa, to reflect normal loads actually experienced in tailings and dams. Long-term flow tests were then conducted during 90 days. In addition, filtration tests modeling the mechanisms involved in the deposition of tailings in a slurry form were performed, using a modified version of ASTM D5101.

All these tests were found to be conclusive and confirmed the applicability of EFDG for tailings dewatering applications based on laboratory evaluations.

The use of Draintube drainage geocomposites under railway infrastructures

Railway construction involves substantial earthworks (embankments and cuttings). Cuttings may reach the water table, and embankments may need preloading when on soft soils. Even during operation of the railway line, the ballast put into place under the railways undergoes densification and degradation over time which reduces the hydraulic conductivity of the material. This phenomenon may affect the durability of the structure if the ballast is not able to evacuate the water during heavy rainfall, flooding or snowmelt. Drainage systems for soil water were traditionally made with granular material layers and perforated collector pipes, one of the main reasons being the ability of that system to support heavy loads over time. As their flow capacity is not load or time sensitive when confined in soil, drainage geocomposites with mini-pipes Draintube are often used instead of the granular drainage layers. At the different stages of the railway construction, it protects the cuttings against high water table, decreases the time for consolidation on soft soils and increases the overall drainage capacity of the system under ballast. It also allows the use of Hydraulically Bound Materials (HBMs) on top of it.

This publication presents a case study for each application, along with the related laboratory study or on-site monitoring. Drainage geocomposites with mini-pipes have been successfully used for 30 years; the product is designed for each project function of the specific site conditions. It requires less machinery to install and reduces the Greenhouse Gas (GHG) emissions compared to a granular material solution.

Design of reinforcement geosynthetics in landfill piggyback expansion

The use of a soil-reinforced layer as a subgrade for a piggyback landfill ensures that the leachate barrier system of the

new cell will remain functional over the long term. The designed and selected PVA reinforcement geosynthetic is a high-modulus woven geotextile made with high-tenacity yarns that exhibit a tensile strength of 2,570 pounds-force per inch (450 kN/m) at 6% strain. It creates a uniform repartition of the load on the old waste and controls the differential settlements.The high-tenacity yarns made of PVA permit the reuse of the bottom ash material (available on-site) as backfill material on the product. The methodology followed for the design of the reinforcement is already in use and described in several guides; however, the implementation of a monitoring system permits refining of the calculation and assumptions considered in the geotechnical model and confirm the expected behavior of the structure.

Use of bi-modulus geosynthetics for the reinforcement of cohesive backfill on cavities

The results of an experimental campaign of reinforcement of thin cohesive soil embankments in the case of cavity collapse are presented. In particular, the aim is to test the effectiveness of a new type of bi-stiffness geosynthetic. A coupled DEM-FEM numerical model is validated based on these results and allows a better understanding of the soilgeosynthetic interaction phenomena mobilized during the collapse. Comparison between the numerical and experimental results obtained with the two types of reinforcement (monostiffness and reversed bi-modulus) make it possible to underline the interest of the innovative product developed.

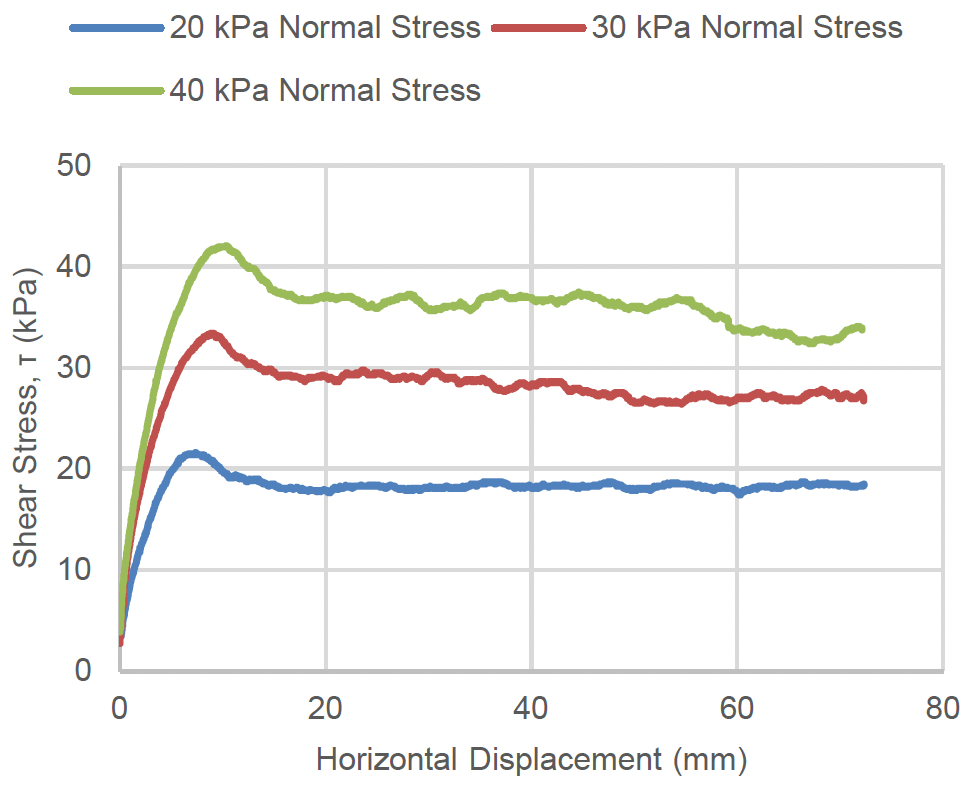

Veneer Stability Evaluation of a Geosynthetic Cover System for Mine Waste Rock

Geomembranes have the potential to be effective barriers in cover systems for mine rock to reduce the influx of atmospheric water and oxygen. However, concerns related to constructability and long-term performance have been a factor in preventing the adoption of this method. The veneer stability of a typical geosynthetic cover system is evaluated for a site containing mine rock composed of shale and limestone. Direct and interface shear tests were completed to measure the angle of internal shearing resistance for soil used in the cover and the angle of interface shearing resistance between each of the potential geosynthetic-geosynthetic and soil-geosynthetic interfaces. The results from this work can assist in the selection of geosynthetic materials and the design slope for a geosynthetic cover system.

Water drainage and gas collection with geocomposites – Hydraulic software development

Geosynthetic materials and, more specifically, drainage geocomposites are now widely used for water drainage and gas collection in applications as varied as final landfill covers, leachate collection in landfill cells, sub-slab depressurization systems under buildings, groundwater drainage under embankments, etc. The design methods used are based on the in-plane flow capacity of the geocomposites, which is determined by laboratory tests performed on 250-300 mm long product specimens. Fluid is injected into the thickness of the product and the drainage capacity is interpolated for an actual length of several meters. This paper presents the development of hydraulic design software for multi-linear drainage geocomposites, based on laboratory characterizations of the geocomposite and then validated with full-scale tests. The software gives a 3D model of the hydraulic curves in the geocomposite depending on the application for which the geocomposite is used, and the fluid to be drained (water, landfill gas, methane, air, etc.).

Innovative Soil Reinforcement Solution with Geotextile Geocells – An Overview

One of the important issues in the construction of geosynthetic reinforced walls is the supply of natural backfill materials with the required properties needed for the stability of the wall. M3S geotextile geocells make it possible, in addition to the construction of reinforced structures with complex shapes, to reuse the soil material excavated on site to build the wall, including those with very poor geotechnical characteristics. For specific sustainment wall case, choosing an adapted soil depends on its compatibility with used geosynthetics and most often on its mechanical parameters (Volumic weight, internal friction angle and cohesive strength) and its compacting ability according GTR manual recommendations. All that parameters come from Standardized Geotechnical Missions (NF P 94-500). Deduced from direct measures or correlations, parameters values are designed and controlled from the start to the end of works. This publication presents a project in a wind farm in France, realized with the M3S cellular system and its mechanical and functional characteristics. It also gives the main design steps to consider, the advantages of this solution and the limits of the system.

Improved QA and QC of Double-Lined Ponds for Processed Water Containment

Processed water storage is one of the main concerns for regulators and owners of operations in the shale gas and the oil sand industry, and for good cause: these extremely pollutant liquids concentrate all the toxic, organic, and chemical parts of the residues that are treated in the facilities. It is therefore necessary to be able to ensure storage under completely leakproof conditions – or at least, the most leakproof conditions we can achieve. Since assembled geomembranes are not 100% free of leaks, it is essential to consider the state of the art in quality assurance and quality control (QA/QC).

Experience all over the world shows that an average of 10 leaks per hectare can generally be found on a lined project where everyone is following the standard QA/QC guidelines (internal QC on site during installation, vacuum box, and basic visual inspection). However, several studies show that the application of additional control practices can lead to an almost zero-defect project to the level detectable. Among these practices is a strong third-party engineer dedicated to improving the quality on site during all stages of the project, from design to operation. The engineer’s tasks will also include leak detection surveys during and after the installation of the geomembranes. These last methods, described by American Society for Testing and Materials (ASTM) standards, can be complicated – or even ineffective – depending on the materials used for the construction and the size of the defect.

Based on a recent case study that is currently occurring in a project related to the mining industry in the USA, this paper will present the importance of those complementary quality controls and the limits of traditional geosynthetic solutions, and will show how conductive multi-linear drainage geocomposites offer an effective solution to enhance the quality of storage ponds, reduce the construction time, and limit environmental risks.

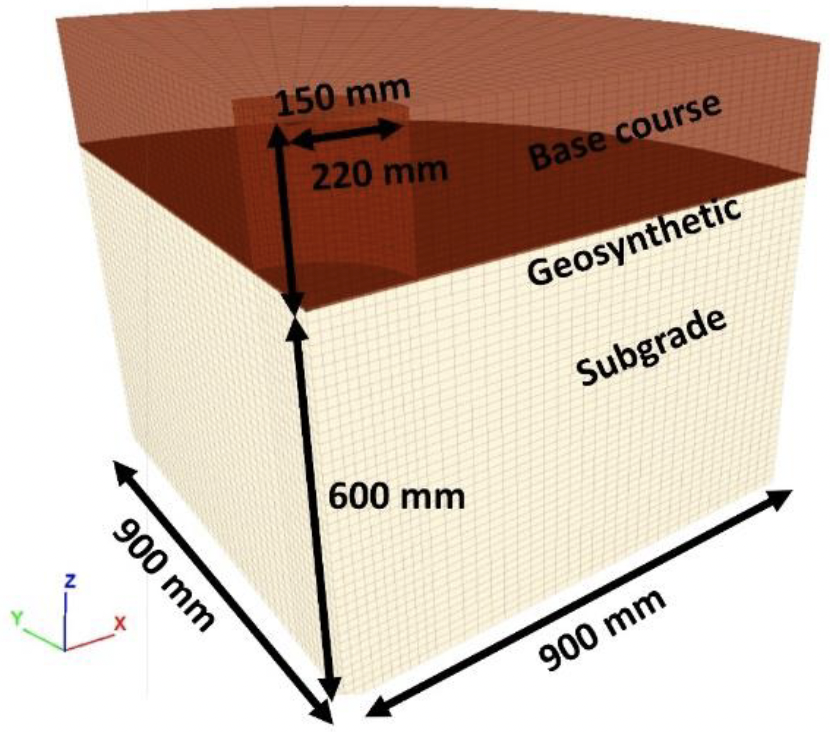

Geosynthetics in unpaved roads on soft subgrade: Large-Scale Experiments and numerical approach

The geosynthetics were used in unpaved roads on soft subgrade since 1970. However, the developed mechanisms in unpaved reinforced roads are complex. To clarify and identify these mechanisms a full-scale laboratory test has been developed. An unpaved reinforced or unreinforced tested platform has been constituted in a laboratory large geotechnical box. The prepared platform was subjected to a cyclic plate load of a maximum magnitude of 40 kN resulting in a surface pressure of 560 kPa. The platform was subjected to 10,000 cycles. Two base course platforms were tested (350 and 220 mm). A knitted geogrid was used in the reinforced platforms. A special attention was given to the soil layers composition, installation, and compaction. The test repeatability was checked. The experimental results showed the geosynthetic benefits in the platforms with a base course thickness of 220 mm. However, for a base course thickness of 350 mm the geosynthetic was not effective. A numerical model was developed using the software FLAC 3D® to simulate the structure behavior under the first applied load. The results showed that the numerical model captures the structure behavior for the reinforced and unreinforced platforms.

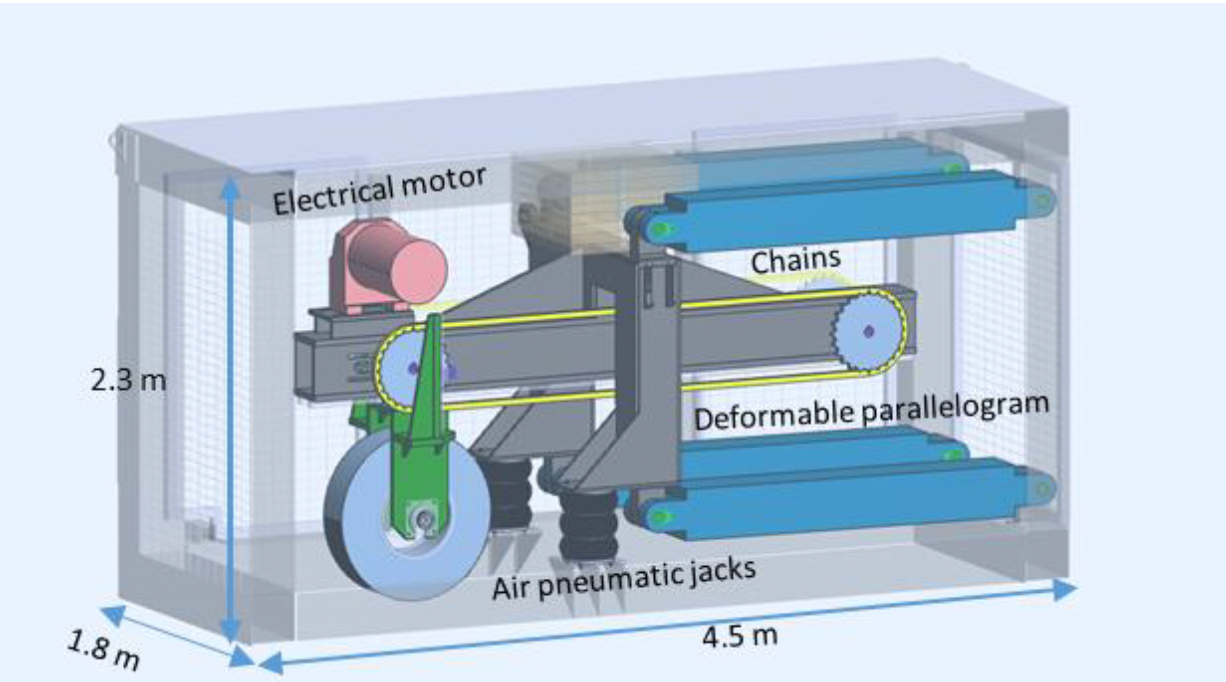

Large-scale test on geosynthetic reinforced unpaved roads on soft subgrade.

Geosynthetics have been widely used since 1970 in unpaved roads. Various research studies showed the benefits of the reinforcement in facilitating the fill material compaction, improving the platform bearing capacity, which will allow the reduction of the fill material thickness, and the increase of the structure serviceability term. Different mechanisms take place between the aggregates platform and the reinforcement. Which affect the structural behavior: the aggregates platform confinement, the separation between the weak subgrade and the fill material, the membrane effect. The road structure becomes even more heterogeneous and the mechanisms more complex with the addition of the reinforcement layer and the underlying mechanics are still not completely understood. Therefore, it is important to provide more knowledge regarding these mechanisms, in order to propose an efficient design method for such structure.

A full-scale laboratory test on unpaved roads has been designed and developed to characterize the effect of the reinforcement in this application. The platform tested is placed in a large box of 5 m in length, 1.9 m in width and 1.4 m in height. The tested platform is composed of 60 cm of weak subgrade supporting 22 cm or 35 cm of well-compacted fill material. A special attention has been given to the soil layers preparation, installation and quality control. The tested structure was subjected to a cyclic plate load and to a circulation traffic load using a large-scale apparatus SAT (Simulator Accelerator of Traffic). This apparatus was developed and adapted for this flexible structure. Indeed, it allows the application of a heavy traffic load on the unpaved road surface even for large surface displacement. During each test, the rut development, the vertical stress distribution and the settlement in the subgrade soil are monitored.

In the present paper, the results of the cyclic plate loading tests are presented. In fact, six tests were performed, two reinforced and unreinforced platforms with 35 cm of base course thickness, and four reinforced and unreinforced tests with 22 cm of base course thickness.

The results are presented in terms of vertical stress distribution on the subgrade surface, and vertical stress and ruts evolution with cycles. The results allowed the verification of the experimental protocol repeatability. Moreover, the comparison between the reinforced and unreinforced platform with different base course thicknesses. In fact, the results of these first tests allowed the protocol preparation for further tests using the SAT apparatus.

PILOT TESTS FOR THE USE OF AFITEX GEOCOMPOSITES IN SLUDGE BASINS OF MEA PROCESSING UNITS

The enrichment of the phosphate ore is currently carried out at the OCP plant by the washing, grinding and flotation process. This type of treatment generates fine and coarse rejections where the sludge fraction (100 to 110 g / L), usually composed of schlamms (<40 μm) and flotation rejects (<125/160 μm), is thickened in decanters to separate water.

About 80-83% of water is generally recovered at the decanter and then recycled to the treatment units. The rest is transferred to the dikes in the form of sludges having a solid concentration ranging from 300 to 350 g/l.

From the dikes, approximately 10 to 12% of water is recovered and then recycled to the treatment units. An important part of this water (about 6 to 8%) remains unrecovered and can be a water that:

- evaporates due to strong sunlight and high temperatures.

- seeps into the soil,

- remains trapped in the sludges.

In order to increase the recovery of the water contained in these sludges, this work was undertaken following the collaboration of the OIK, R&D and AFITEX teams. The main objective is to carry out pilot basin tests to develop and assess the good functioning of a range of drainage's geocomposites for a better recovery of the water from the dikes and a good stability of the walls of the basins.

The results of these tests highlighted several interests of the Draintube (geocomposite) compared to the

traditional solution of the natural basin.

- Solid percentage less than 1% in the recovered filtrate. This makes it reusable at the treatment units,

- protection of dikes from erosion and instability at the basin slope;

- at the bottom of the basin:

- optimized drainage;

- recovery of 20% more filtrate than with the traditional basin;

- limitation of surface evaporation of the basin;

- drying up a large volume of sludge over a short period of time.

- Preservation of groundwater by limiting infiltration through ponds.

Developing a waterproofing geocomposite for railway platform s in evolving materials area

As part of the building of new high-speed lines in France and Morocco (Tanger-Kenitra), a waterproof geocomposite has been developed to answer time, space and money constraints of these particular worksites. This new geocomposite has been designed to meet the technical standards of French National Railway company (SNCF); it protects the railway platform against water infiltrations in sensitive-to-water areas.

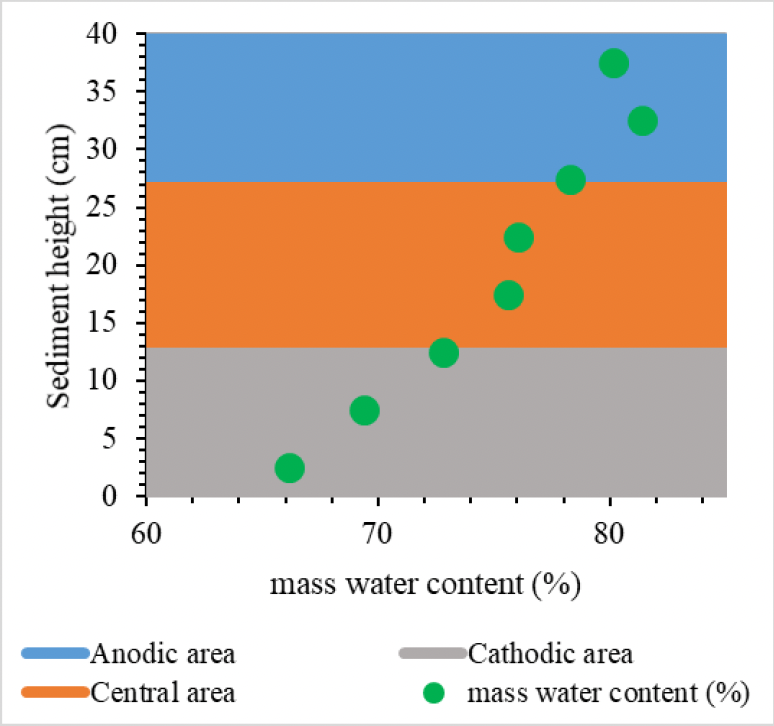

Innovative geocomposite for dredged sediments depollution

In France, sediments from river dredging are considered as waste. Without any special treatment, they must be stored in landfills. The dredged sediments of our area of study (North of France) are polluted with trace metals (antimony and zinc are above the French regulation threshold). The main objective of this study is to develop a new method of active depollution and dewatering treatment in order to enable the reuse of treated sediments. This treatment is carried out through ponds equipped with innovative geocomposite. This innovative geocomposite has two typical passive functions (filtration and drainage). In addition, it is functionalized by an innovative electrokinetic technology to confer it active roles (depollution and dewatering). Electrokinetic consists in applying a difference of electrical potential to a porous medium. We present here the results of a preliminary laboratory study that simulates this new method on a short-term (3 weeks) experiment. The results show that the electrokinetic treatment has an impact on the chemical and physical properties of sediments. The treatment reduces by 50% the concentration of zinc in the leachate after lixiviation.

Drainage Improvement Under Railways with the Use of a Drainage Geocomposite

Railway construction involves important earthworks (embankments and cuttings). Cuttings may reach the water table, embankments may need preloading when on soft soils. Even during operation of the railway line, under the action of cyclic loads due to the passage of trains, the ballast put into place under the railways undergoes densification and degradation over time which reduces the void index and thus the hydraulic conductivity of the material. This phenomenon may be critical for the durability of the structure if the ballast is not able to quickly evacuate the water, especially during heavy rainfall, flooding and/or snowmelt. The installation of a drainage geocomposite with mini-pipes Drain Tube at these different stages allows protection against high water table on the cutting, decreases the time for consolidation on soft soils and increases the overall drainage capacity of the system under ballast.

This publication presents a case study for each application along with the related laboratory study or on-site monitoring. Drainage geocomposites with mini-pipes Drain Tube has been successfully utilized for 30 years, the main advantages being the high drainage capacity of the product under high loads in addition to the non-sensitivity to creep when confined and its robustness.

Exposed NPNW GT Performance at a Large Surface Impoundment For Nearly One Year

Exposed needle punched nonwoven (NPNW) Geotextiles are uncommon in Civil Engineering applications. Most specifications limit their exposure to a few weeks after installation due to the threat of UV degradation. This very unusual case history allowed us to evaluate an exposed NPNW geotextile over a long period of time (8 months). In addition, we performed laboratory UV exposure tests to counterpoint field versus lab performance and develop correlations between different methods of exposure.

Efficacy of Nonwoven Based Geosynthetic Drainage Product for Pore Pressure Reduction in Moderately Fine Soils or Tailings

A common challenge in geotechnical engineering is to reduce pore pressures in fine-grained soils or tailings and geosynthetic drainage may be proposed for such applications. Depending on the relative unsaturated permeability of soil and geotextile, a capillary break may develop, resulting in higher water content in the soil along with increased pore pressure (or lower suction) and consequent decrease in factor of safety against slope failure. While high (saturated) geotextile permeability may be desirable under some conditions, formation of a capillary break inhibits drainage and compromises overall performance of the soil/geosynthetic system. In this study, the water characteristic curve (GWCC) was measured for a common geocomposite drainage product. An unsaturated permeameter was used to measure permeability under limited matric suction. The applicability of the Fredlund-Xing equation to estimate unsaturated permeability from the GWCC was confirmed. A series of transient and steady-state experiments were carried out in a lab-scale physical model with two different silt-sized soils to confirm that the unsaturated behaviour of the soil/geosynthetic composite system could be predicted by independent laboratory measurements of the two materials. Finally, numerical simulations were conducted of the performance of the drainage product in reducing pore-pressures in an unsaturated embankment subject to rainfall.

Design of Reinforcement Geosynthetics in Landfill Piggyback Expansion

The construction of a vertical expansion of existing waste disposal facilities (piggyback landfills) involves the use of reinforcement geosynthetics to address differential settlements and stability that will be reactivated under the load of the new cell. The challenge is to guarantee the integrity of the new liner system. This paper presents the extension project of an old landfill and the design method used to evaluate the tensile strength of the required reinforcement geosynthetic.

The methodology used in this project is a calculation method for the design of geosynthetics in the case of soil subsidence and sinkholes. This reference method, usually used with granular backfill, has been adapted and optimized to consider waste material-specific properties.

Life cycle analysis of an innovative reinforcement geosynthetic coupled with a detection and monitoring warning system

The use of reinforcement geosynthetics to prevent localized collapses over cavities is now relatively common. During the REGIC research project, an innovative geosynthetic solution has been developed. It includes a specific reinforcement geosynthetic coupled with an autonomous and remote warning device to detect, to locate and then monitor a localized collapse or sinkhole. This study identifies technically and environmentally the implementation conditions of this innovative instrumented geosynthetic solution compared to the traditional solution. The Life Cycle Analysis is realized to carry out this comparison from an environmental point of view.

The results, including a sensitivity analysis aim to provide information on the environmental performance of the developed instrumented solution in a R&D framework. This detailed analysis is extended to most current other possible solutions with same level of performance and safety. This life cycle analysis finally resulted in the publication of an EPD for the geosynthetic range concerned.

Multi-linear drainage geocomposite for sub-slab depressurization and radon mitigation

Sub-slab Depressurization (SSD) aims to reduce building occupants’ exposure to toxic gases from the soil. These gases can either be generated from contaminated soils (like Volatile Organic Compounds or Landfill Gas) or naturally present in the soil (like Radon). The SSD system is composed from the bottom to the top of a separator geotextile, a drainage layer, and a vapor barrier. One or more gas pits are located according to the gas concentration in the area and to the geometry of the building. Because most of the SSD systems are constructed in high-density population areas (e.g., new construction in old industrial zones), the truck traffic and the noise resulting from the excavation works, and the transportation of granular material is a nuisance for residents. It also damages the local road network that is not designed to handle heavy vehicles traffic. This paper presents the sizing and the use of multi-linear drainage geocomposite as part of the SSD system providing separation and gas collection functions. The geocomposite is composed of non-woven geotextile layers incorporating perforated mini-pipes regularly spaced and running the roll length. It is connected to a collector pipe and to the gas pit. It collects the soil gas and reduces the head losses thanks to the high-density network of perforated mini-pipes within the product and the specific fittings used to connect the product to the main collector pipe. The sizing of the geocomposite is done using laboratory tests and software to characterize the flow capacity and the head losses of the system. Multi-linear drainage geocomposites have been found to be efficient for both passive and active SSD systems.

Use of bi-modulus geosynthetics for the reinforcement of cohesive backfill on cavities

The results of an experimental campaign of reinforcement of thin cohesive soil embankments in the case of cavity collapse are presented. In particular, the aim is to test the effectiveness of a new type of bi-stiffness geosynthetic. A coupled DEM-FEM numerical model is validated based on these results and allows a better understanding of the soilgeosynthetic interaction phenomena mobilized during the collapse.

Comparison between the numerical and experimental results obtained with the two types of reinforcement (monostiffness and reversed bi-modulus) make it possible to underline the interest of the innovative product developed.

Water drainage and gas collection with geocomposites – Hydraulic software development

Geosynthetic materials and, more specifically, drainage geocomposites are now widely used for water drainage and gas collection in applications as varied as final landfill covers, leachate collection in landfill cells, sub-slab depressurization systems under buildings, groundwater drainage under embankments, etc. The design methods used are based on the in-plane flow capacity of the geocomposites, which is determined by laboratory tests performed on 250-300 mm long product specimens. Fluid is injected into the thickness of the product and the drainage capacity is interpolated for an actual length of several

meters. This paper presents the development of hydraulic design software for multi-linear drainage geocomposites, based on laboratory characterizations of the geocomposite and then validated with full-scale tests. The software gives a 3D model of the hydraulic curves in the geocomposite depending on the application for which the geocomposite is used, and the fluid to be drained (water, landfill gas, methane, air, etc.).

Improving railway drainage with multilinear geocomposites

In this article published by the Geosynthetics Magazine, the authors Stephan Fourmont, Business Development Manager at AfitexTexel, and Mathilde Riot, Technical and R&D at Afitexinov, assert, through three illustrative cases studies, that significantly improving railway drainage is possible using multi-linear drainage geocomposites, such as DRAINTUBE®.

Read the full article below or on the website of Geosynthetics Magazine.

Recommendations for the use of geosynthetic reinforcement to reduce the risks associated with a localised collapse

Road and urban infrastructures are sometimes confronted with damages caused by localised collapses. Mitigation of this damage can be achieved with instrumented geosynthetic reinforcement. This recommendation guide provides a presentation of the different types of cavities and the ground movements that can be induced by localised collapses, available treatment methods to reduce the vulnerability, a description of reinforcement method by geosynthetics for granular and cohesive soil, especially the "bi-modulus" instrumented geosynthetic developed in the REGIC project and a methodological recommendations for the use of instrumented geosynthetics.

Innovative mechanically stabilized earth walls with geotextiles geocells

Structures reinforced with geosynthetics consist in increasing the mechanical performance of a soil (mainly shear resistance) by associating it with flexible geosynthetics inclusions. One of the important issues in the construction of geosynthetic reinforced walls is the supply of natural backfill materials with the required properties needed for the stability of the wall. Indeed, unlike geosynthetics that exhibit stable properties due to extensive quality controls during the manufacturing process, soil matrix will vary from a site to another and even from the beginning to the end of the excavation work. It influences the soil stability itself and also the soil-geosynthetic interface. As it minimizes the influence of soil characteristics on the stability of the reinforced structure, M3S geotextile geocells make possible, in addition to the construction of reinforced structures with complex shapes, to reuse the soil material excavated on-site to build the wall, including those with very poor geotechnical characteristics. This publication presents the M3S cellular system and its mechanical and functional characteristics. It also gives a case study on the construction in 2019 of two MSE walls as part of the A71 motorway bypass on the APRR network, France.

Developed full-scale cyclic plate load and traffic load tests for unpaved roads on soft subgrade and reinforced with geosynthetics

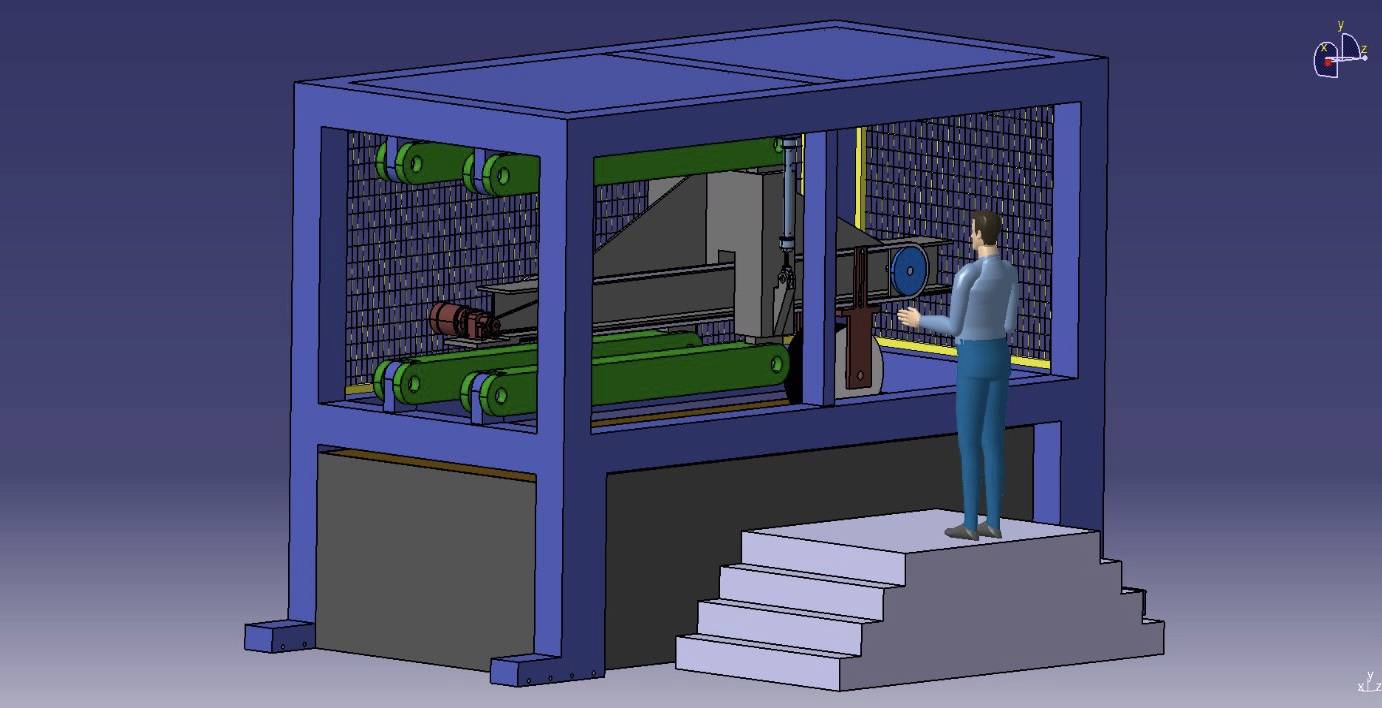

With the expansion of urban areas, the construction on soft subgrade becomes a more often issue due to excessive settlement, especially for roads network. Nowadays, the tradition soft soil replacement solution is substituted by stabilization solutions to reduce the surface settlement. Geosynthetics (GSYs) are used to stabilize base course over soft subgrade under unpaved roads. GSYs improve this structure by the following mechanisms : lateral restraint and reinforcement of base course aggregates, tension membrane effect in rutted areas, and reduction of mixing between subgrade and base soils. With the reinforcement addition, the mechanisms developed at the interface become even more complex. It is important to identify and clarify these mechanisms in order to propose an efficient design method for this kind of structure. A large-scale laboratory test was designed and developed to characterize the GSYs effects and the reinforcement mechanisms in unpaved roads. An unpaved road platform was subjected to cyclic plate load. The platform consisted of a soft subgrade layer supporting a base course layer and placed in a box of 1.9 m of large, 1.8 m of length and 1.1 m of height. The composition of soft soil, the installation and the quality control procedure are detailed in this paper. The surface rutting, the subgrade settlement and the vertical stress distribution were monitored during the loading cycles. Moreover, the GSY strain was monitored using the fibre optic technology. Six tests were performed; two repeatability tests and four reinforced and unreinforced tests with different base course thicknesses. The tests performed proved the repeatability of the experimental protocol. Moreover, it is concluded that the used GSY has a negligible effect if the base course thickness is equal or higher than 350 mm. On the other hand, for a base course thickness of 220 mm, the geogrid reinforcement provides a surface rutting reduction of 22%, and a subgrade central vertical stress reduction of 30%. In comparison with the empirical and the analytical design methods from the literature, we conclude that these methods overestimate the base course thickness for unreinforced platform. These experiments consist in a preparation program to a full-scale experiment, with a cyclic Traffic load applied on the unpaved road surface, using the Simulator Accelerator of Traffic (SAT) machine developed at INSA Lyon.

Large-scale test on geosynthetic reinforced unpaved roads on soft subgrade

Geosynthetics have been widely used since 1970 in unpaved roads. Various research studies showed the benefits of the reinforcement in facilitating the fill material compaction, improving the platform bearing capacity, which will allow the reduction of the fill material thickness, and the increase of the structure serviceability term. Different mechanisms take place between the aggregates platform and the reinforcement. Which affect the structural behavior: the aggregates platform confinement, the separation between the weak subgrade and the fill material, the membrane effect. The road structure becomes even more heterogeneous and the mechanisms more complex with the addition of the reinforcement layer and the underlying mechanics are still not completely understood. Therefore, it is important to provide more knowledge regarding these mechanisms, in order to propose an efficient design method for such structure. A full-scale laboratory test on unpaved roads has been designed and developed to characterize the effect of the reinforcement in this application. The platform tested is placed in a large box of 5 m in length, 1.9 m in width and 1.4 m in height. The tested platform is composed of 60 cm of weak subgrade supporting 22 cm or 35 cm of well-compacted fill material. A special attention has been given to the soil layers preparation, installation and quality control. The tested structure was subjected to a cyclic plate load and to a circulation traffic load using a large-scale apparatus SAT (Simulator Accelerator of Traffic). This apparatus was developed and adapted for this flexible structure. Indeed, it allows the application of a heavy traffic load on the unpaved road surface even for large surface displacement. During each test, the rut development, the vertical stress distribution and the settlement in the subgrade soil are monitored.

Geosynthetics in unpaved roads on soft subgrade : Large-Scale Experiments

The geosynthetics were used in unpaved roads on soft subgrade since 1970. However, the developed mechanisms in unpaved reinforced roads are complex. In order to clarify and identify these mechanisms a full-scale laboratory test has been developed. An unpaved reinforced or unreinforced tested platform has been constituted in a laboratory large geotechnical box. The prepared platform was subjected to a cyclic plate load of a maximum magnitude of 40 kN resulting in a surface pressure of 560 kPa. The platform was subjected to 1,000 cycles. Two base course platform were tested (350 and 220 mm). A knitted geogrid was used in the reinforced platforms. A special attention was given to the soil layers composition, installation and compaction. The test repeatability was checked. The experimental results showed the reinforcement benefits in the platforms with a base course thickness of 220 mm. However, for a base course thickness of 350 mm the reinforcement was not effective. A numerical model was developed using the software FLAC 3D® to simulate the structure behavior under the first applied load. The results showed that the numerical model captures the structure behavior for the reinforced and unreinforced platforms.

On the performance of geogrids for asphalt pavement reinforcement : laboratory evaluation and selected case studies

The use of geogrids for pavement reinforcement has been continuously increasing over the past decades. Their main role remains to limit crack reflection and they are therefore typically used on cracked pavements before renovating the upper asphalt layers. Still, evaluating their performance is not a simple task because most available testing methods are still at an early development stage with sometimes limited field validation. As a consequence, no clear guidelines currently exists for selecting this type of products in preparation of a construction project. This paper presents the laboratory results gathered so far on fiber-glass reinforced geocomposites in view of their use in real jobsites. Fatigue testing and the potential to delay crack reflection as measured with the Cerema Autun device, are presented and discussed in the light of recent jobsites on Paris Charles de Gaulle Airport and French highway A7. In addition, the correct positioning of the geogrids on the asphalt support was further evaluated using the Leutner test. This clarifies the conditions under which the placement of these materials will be optimized. From this work, a clearer picture tends to emerge on how to specify these very specific products in order to maximize their benefit for extending pavement life time.

Retaining walls with high weight concrete blocks in association with geosynthetics

Geosynthetic reinforced retaining walls with cellular facing are well-known and mastered technics commonly used in France and around the world. This technic combines cellular blocks (such as concrete, gabion baskets…) with high modulus reinforcement geosynthetics and allows the retaining wall to resists stresses on very high heights. However, the installation procedure of these blocks knows some limits for great projects such as the duration of installation or how to deal with a draining system behind the facing. That’s why the idea of the creation of a block with new size, new weight and new composition came on the table. This concrete block with almost 1 m² of facing area per block and 700 kg empty allows the use of an hybrid solution part-weight/part-geosynthetic reinforcement while ensuring an extremely fast and easy on-site installation with classical lifting engines.

Optimization of Geosynthetic Design for Asphalt Pavement Reinforcement

The use of geogrids for pavement reinforcement has been continuously increasing over the past decades. Their main role remains to limit crack reflection and they are therefore typically used on cracked pavements before renovating the upper asphalt layers. Still, the way they work remains a debated issue and no clear guidelines currently exist for selecting this type of products in view of a specific construction project. This paper presents our current understanding of the mechanisms behind asphalt pavement reinforcement in view of the 3 functions described in the European standard for these products (EN 15381), namely stress relief, reinforcement and interlayer barrier. As a consequence, an optimal geosynthetic design can be inferred, based on the combination of a fiber-glass geogrid and a light geotextile as exemplified by the Geoter® FNG product range developed at Afitexinov. The interest of these products is discussed and illustrated in the light of recent results.

Use of multi-linear drainage geocomposites for CCP disposal units final cover

In the event that a final cover is used to close a CCP disposal area, the cover system has to meet or exceed the EPA requirements. Regarding the drainage layer component, the use of Multi-Linear Drainage Geocomposite (MLDG) permits to collect and evacuate the infiltration water. MLDG like Drain Tube have embedded corrugated perforated mini-pipes regularly spaced between two non-woven geotextile layers. They enable water to be evacuated at a higher rate than an homogeneous drainage layer (Del Greco et al., Politecnico di Torino, Italy, 2012) even if the drainage slope is zero. Because differential settlement over time is one of the main concerns for CCP Landfill and Impoundment closures, Drain Tube will drain efficiently water and limit its accumulation even if differential settlements occur thanks to its directional behavior (drainage in the direction of the mini-pipes). The effective drainage capacity of the Drain Tube geocomposite which is a function of the distance between the mini-pipes in the product, is determined using GRI GC15 and ASTM D4716 standards. After Blond et al., 2010 and as per ASTM D7931 standard recommendation, the long-term drainage capacity of tubular drainage geocomposites is not affected by creep in compression nor geotextile intrusion when confined in soil. These two reduction factors RFCR and RFIN must be taken equal to 1.0 in the design of the drainage layer with a MLDG such a Drain Tube. This leads to a cost reduction and a higher factor of safety for the drainage layer.

Improved QAQC of double-lined ponds for processed water containment

Processed water storage is one of the main concerns for regulators and owners of operations in the shale gas and the oil sand industry, and for good cause: these extremely pollutant liquids concentrate all the toxic, organic, and chemical parts of the residues that are treated in the facilities. It is therefore necessary to be able to ensure storage under completely leakproof conditions – or at least, the most leakproof conditions we can achieve. Since assembled geomembranes are not 100% free of leaks, it is essential to consider the state of the art in quality assurance and quality control (QA/QC). Experience all over the world shows that an average of 10 leaks per hectare can generally be found on a lined project where everyone is following the standard QA/QC guidelines (internal QC on site during installation, vacuum box, and basic visual inspection). However, several studies show that the application of additional control practices can lead to an almost zero-defect project to the level detectable. Among these practices is a strong third-party engineer dedicated to improving the quality on site during all stages of the project, from design to operation. The engineer’s tasks will also include leak detection surveys during and after the installation of the geomembranes. These last methods, described by American Society for Testing and Materials (ASTM) standards, can be complicated – or even ineffective – depending on the materials used for the construction and the size of the defect. Based on a recent case study that is currently occurring in a project related to the mining industry in the USA, this paper will present the importance of those complementary quality controls and the limits of traditional geosynthetic solutions, and will show how conductive multi-linear drainage geocomposites offer an effective solution to enhance the quality of storage ponds, reduce the construction time, and limit environmental risks.

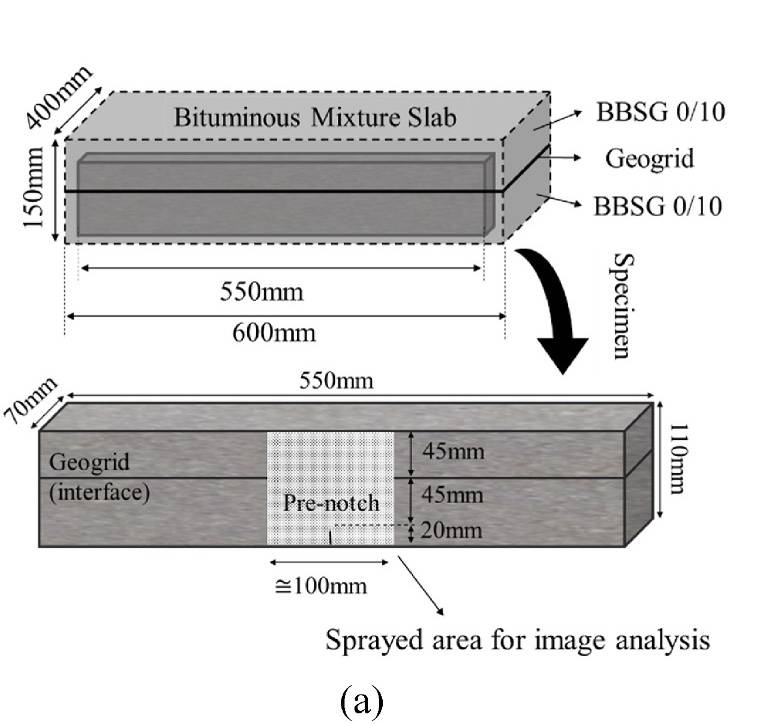

Crack propagation OF BITUMINOUS MIXTURES reinforced by GEOGRIDS using digital image correlation

In the rehabilitation of flexible pavements, the reinforcement by geogrids has substantially increased recently, aiming to extend the service life of pavements. This work aims at evaluating the effect of fiberglass geogrid reinforcement in crack propagation of bituminous mixtures. To conduct the research, five pre-notched beams constituted of two bituminous mixtures layers, with and without geogrid, were tested. Two different fiberglass geogrids, maximum strength resistance of 100 and 50kN/m, and two types of emulsion as tack coat to glue the geogrid on the bituminous mixture layers, were combined for fabrication of three reinforced specimens. Also, two unreinforced specimens were also fabricated. One beam is composed by two bituminous mixtures layers glued by emulsion. The last beam, having the same size, is made of a single bituminous mixture layer. The specimens were subjected to the four-point bending notched fracture (FPBNF) tests, designed at the University of Lyon/ENTPE. A 3D Digital Image Correlation (DIC) device was used to determine the strain evolution around the crack and the crack tip location during the tests. The results showed that the effect of the geogrid is clearly noticeable when the specimen is subjected to high strain and the crack starts to propagate into the beams.

Protection of Building Against Soil Gas Infiltrations Using Drainage Geocomposites

Construction of buildings on natural or degraded layers with the potential to generate gasses (biogas from waste, gas emission from polluted soils, radon, etc.) requires the installation of a gas collection and evacuation system to protect the health of the building’s inhabitants. Replacing crushed stone drainage layers using perforated collector pipers with a multi-linear drainage geocomposite composed of non-woven geotextile layers, needle-punched together with perforated and corrugated polypropylene pipes regularly spaced inside, typically every 1 m (40 in.), allows for the collection of gasses across the covered surface and significantly reduces excavation work and worksite traffic. As part of an active or passive subslab depressurization system, multi-linear drainage geocomposites reduce vacuum dissipations. A specific set of connectors is available to optimize the connections between the geocomposite layer and the collection pipes.

Innovative Soil Reinforcement Solution with Geotextile Geocells – An Overview

One of the important issues in the construction of geosynthetic reinforced walls is the supply of natural backfill materials with the required properties needed for the stability of the wall. M3S geotextile geocells make it possible, in addition to the construction of reinforced structures with complex shapes, to reuse the soil material excavated on site to build the wall, including those with very poor geotechnical characteristics. For specific sustainment wall case, choosing an adapted soil depends on its compatibility with used geosynthetics and most often on its mechanical parameters (Volumic weight, internal friction angle and cohesive strength) and its compacting ability according GTR manual recommendations. All that parameters come from Standardized Geotechnical Missions (NF P 94-500). Deduced from direct measures or correlations, parameters values are designed and controlled from the start to the end of works. This publication presents a project in a wind farm in France, realized with the M3S cellular system and its mechanical and functional characteristics. It also gives the main design steps to consider, the advantages of this solution and the limits of the system.

Drainage Improvement Under Railways with the use of a drainage geocomposite

Railway construction involves important earthworks (embankments and cuttings). Cuttings may reach the water table, embankments may need preloading when on soft soils. Even during operation of the railway line, under the action of cyclic loads due to the passage of trains, the ballast put into place under the railways undergoes densification and degradation over time which reduces the void index and thus the hydraulic conductivity of the material. This phenomenon may be critical for the durability of the structure if the ballast is not able to quickly evacuate the water, especially during heavy rainfall, flooding and/or snowmelt. The installation of a drainage geocomposite with mini-pipes Drain Tube at these different stages allows protection against high water table on the cutting, decreases the time for consolidation on soft soils and increases the overall drainage capacity of the system under ballast.

This publication presents a case study for each application along with the related laboratory study or on-site monitoring. Drainage geocomposites with mini-pipes Drain Tube has been successfully utilized for 30 years, the main advantages being the high drainage capacity of the product under high loads in addition to the non-sensitivity to creep when confined and its robustness.

Smart geosynthetics for strain measurements in asphalt pavements

The paper presents first the pit pavement and asphalt pavement construction. Then, the signals obtained from the sensors are presented. They were measured once a truck, loaded at various weights, was circulated over the structure. Calculations using pavement design software allowed computing the expected strains in the pavement. The comparison between theoretical and experimental data from both smart geosynthetic and standard strain gauges, clearly shows the superiority of this new generation of sensors over traditional ones. Clearly, this new technology for strain measurements in pavements can replace traditional strain gages in a very simple way. Apart from obvious pavement monitoring, these devices can also be used for many other potential applications such as weigh-in-motion (WIM) system.

Lessons learned on the Performance of Multi-Linear Drainage Geocomposites for Mining Applications